PCTG - Smooth and Transparent

PCTG (Polycyclohexylenedimethylene Terephthalate Glycol-modified) is a relatively new copolyester filament gaining significant traction in the 3D printing community. It offers a compelling blend of properties that make it a superior alternative to PETG in many applications, particularly when enhanced toughness, clarity, and ease of printing are desired.

Key Characteristics:

Exceptional Toughness & Impact Resistance: PCTG boasts significantly higher impact strength compared to PETG, making it an excellent choice for parts that need to withstand significant stress, drops, or collisions. This makes it ideal for functional prototypes, protective components, and mechanical parts.

High Transparency/Clarity: While PETG can be somewhat clear, PCTG often offers superior optical clarity, approaching that of acrylic. This makes it suitable for applications requiring light transmission, such as protective covers, enclosures for electronics, or even artistic prints where transparency is key.

Good Heat Resistance: Similar to PETG, PCTG offers good heat deflection temperature, allowing it to maintain its structural integrity in environments with elevated temperatures, though generally not as high as materials like ABS or ASA.

Chemical Resistance: PCTG exhibits good resistance to a variety of chemicals, including many acids, bases, and solvents, contributing to its durability and longevity in diverse applications.

Low Odor & Emissions: Compared to some other filaments like ABS, PCTG produces very low odor during printing, making it more pleasant to work with, especially in enclosed spaces. It also has low VOC (Volatile Organic Compound) emissions.

Ease of Printing: One of PCTG's standout features is its printability. It generally adheres well to various build surfaces with minimal warping, bridging, or stringing issues. It also tends to be less prone to moisture absorption than PETG, leading to more consistent prints.

Post-Processing Friendly: PCTG can be easily sanded, machined, and painted, allowing for good post-processing flexibility to achieve desired finishes or integrate printed parts into larger assemblies.

Food-Safe (Potential): Like PETG, certain formulations of PCTG can be food-safe, making it suitable for applications that come into contact with food or beverages. Always verify specific filament certifications for food-safe applications.

Common Applications:

Functional Prototypes: Due to its strength and ease of printing.

Mechanical Parts: Gears, brackets, housings, and other components requiring durability.

Protective Components: Guards, cases, and covers for electronics or machinery.

Transparent Enclosures: For electronics, displays, or artistic projects.

Vases and Decorative Items: Where clarity and strength are desired.

Automotive Parts: Interior components or non-structural exterior parts.

Jigs and Fixtures: For manufacturing or assembly processes.

Printing Considerations:

Nozzle Temperature: Typically between 230°C and 260°C.

Bed Temperature: Usually 70°C to 90°C.

Print Speed: Similar to PETG, moderate speeds are recommended for best results.

Cooling Fan: Often used at a low percentage (e.g., 0-50%) to prevent excessive cooling and improve layer adhesion, similar to PETG.

Adhesion: Blue painter's tape, PEI sheets, or glues sticks often work well.

In Summary:

PCTG represents a significant advancement in 3D printing filaments, offering a compelling combination of extreme toughness, excellent clarity, and user-friendly printability. It stands as a robust and reliable alternative to PETG, particularly for applications demanding higher impact resistance and superior optical properties, making it a valuable addition to any 3D printing enthusiast's or professional's material arsenal.

Supported Colors

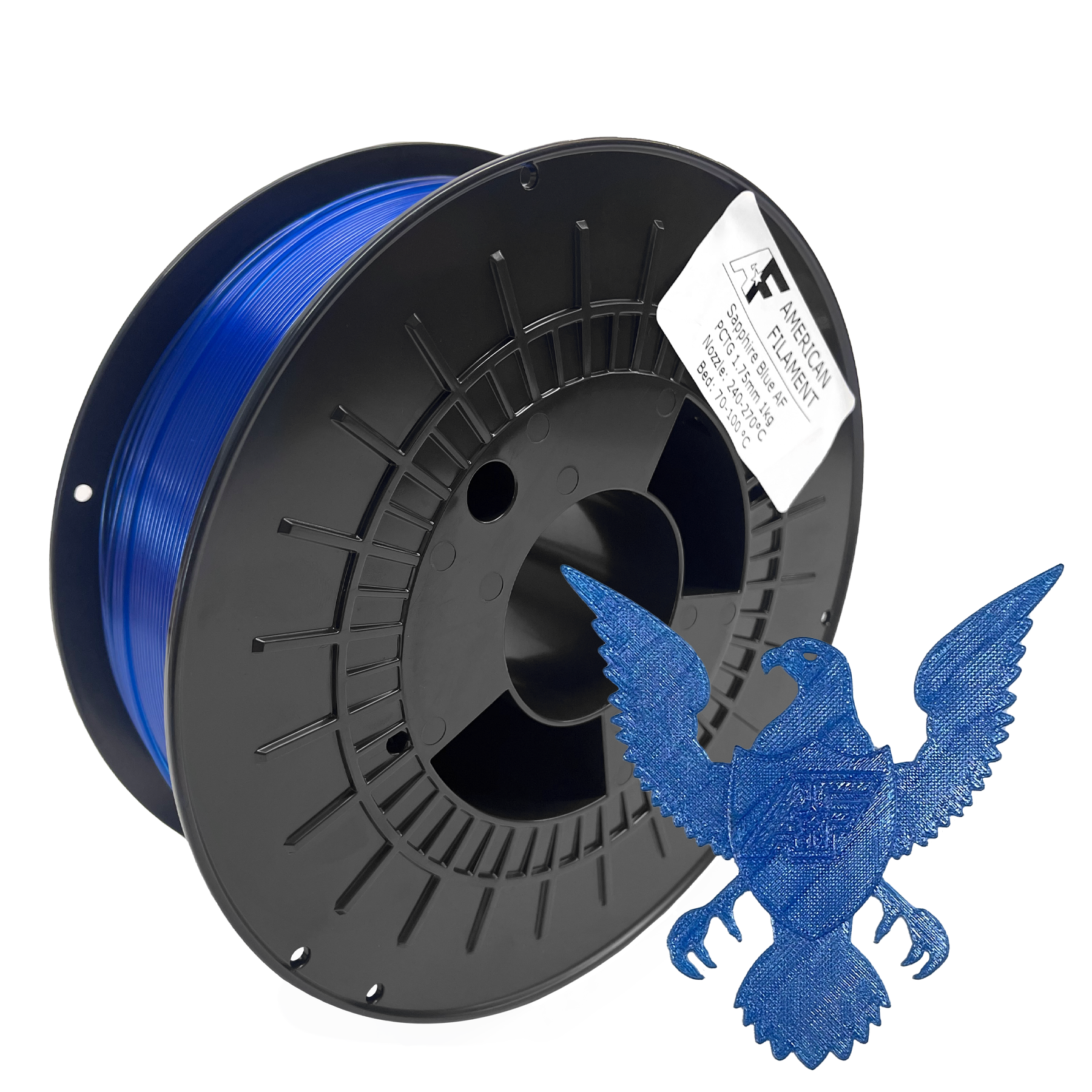

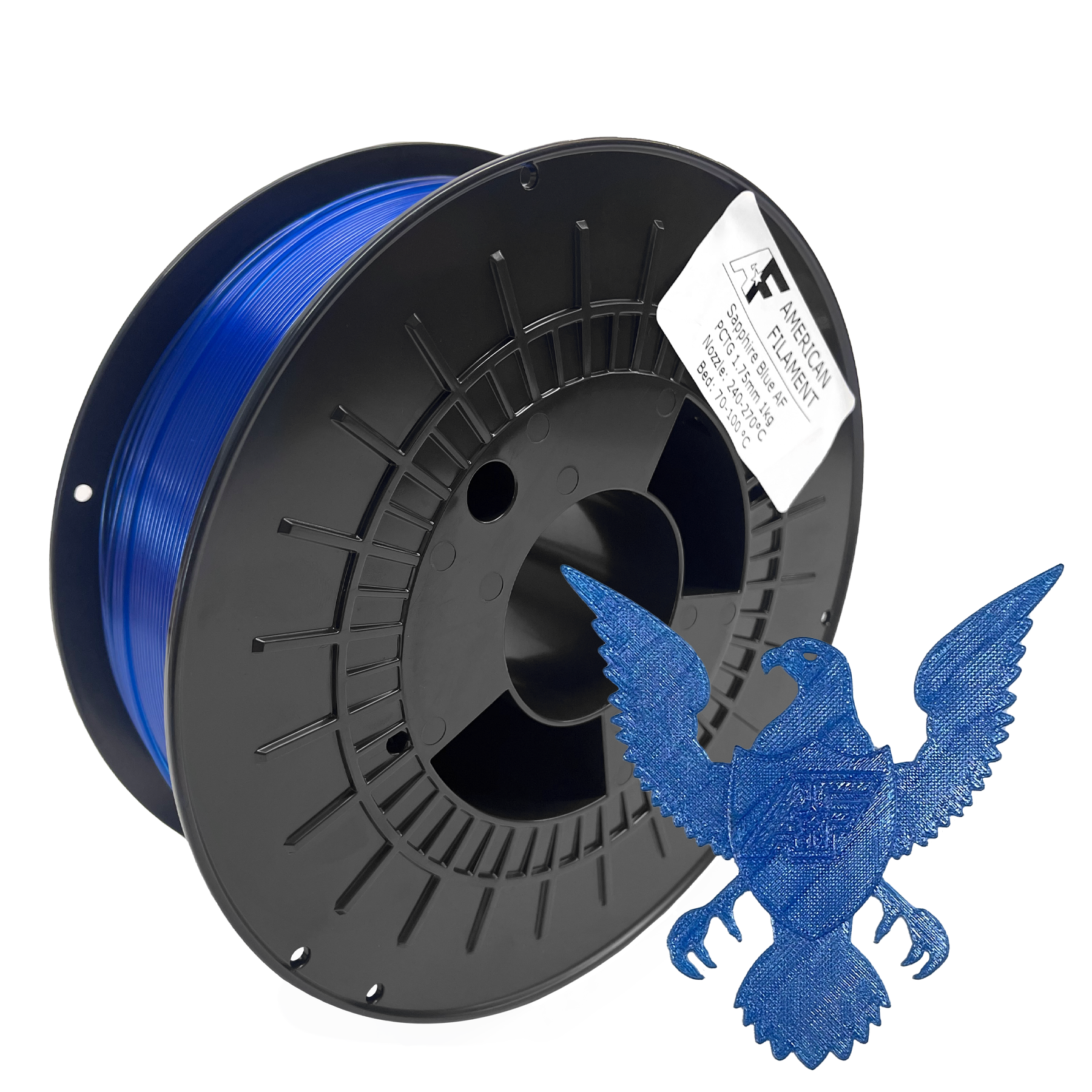

AF Sapphire Blue Transparent PCTG

Spools On The Rack

No spools found.

Available Spools

No spools found.