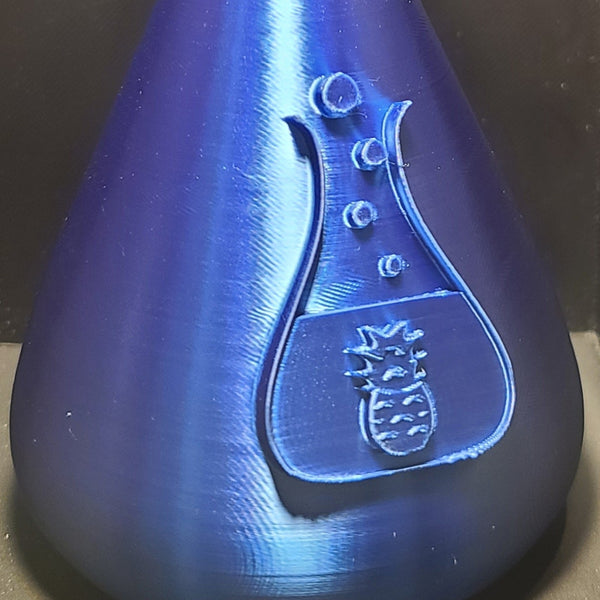

PLA

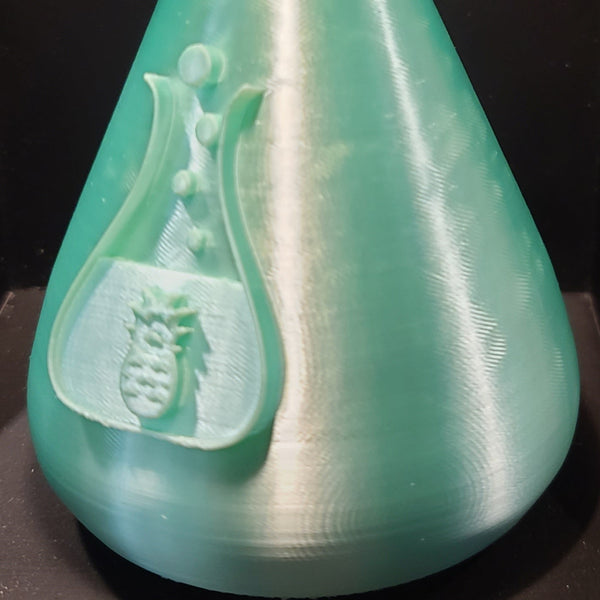

PETG

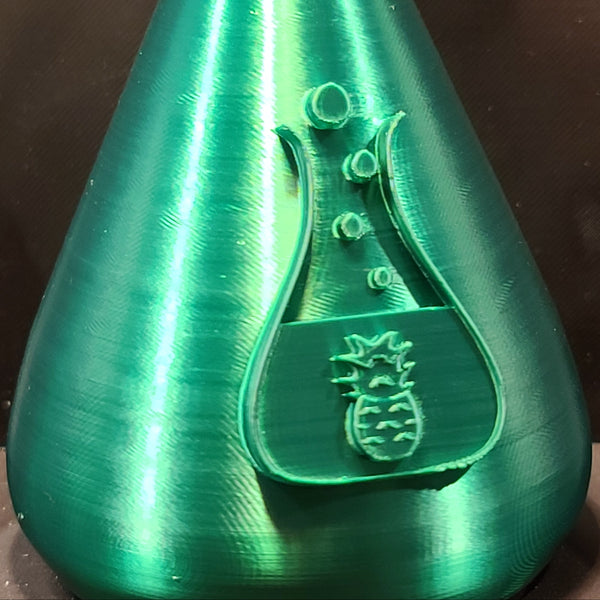

PCTG

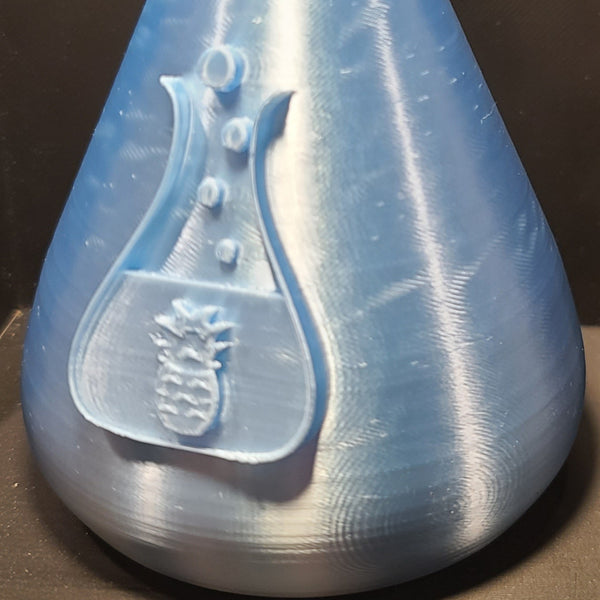

ASA

Polycarbonate

PA6-GF (Nylon W/ Glass Fibers)

Thermoplastic polyurethane (TPU)

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular price

Vendor:

Product vendor

Product title

Regular price $50.00 USD Sale price $50.00 USD Regular priceStandard PLA+ Colors: Quality You Can Trust

After-Dark Designs: High-Intensity Glow

Metallic Sheen PLA: Our Silk+ Color Palette

Zero Glare: The Professional Matte Collection

The Outdoor-Grade Material - ASA

TPU - Custom Seals, Grommets, and Dampening

Extreme Impact Strength - Polycarbonate

Superior thermal stability - PA6-GF (Nylon)